Being interested in tech, food and having a chemical engineering degree this is a personal favourite topic of mine (and may be a bit of a rant). Pasteurization is all about statistics and killin’ microbes.

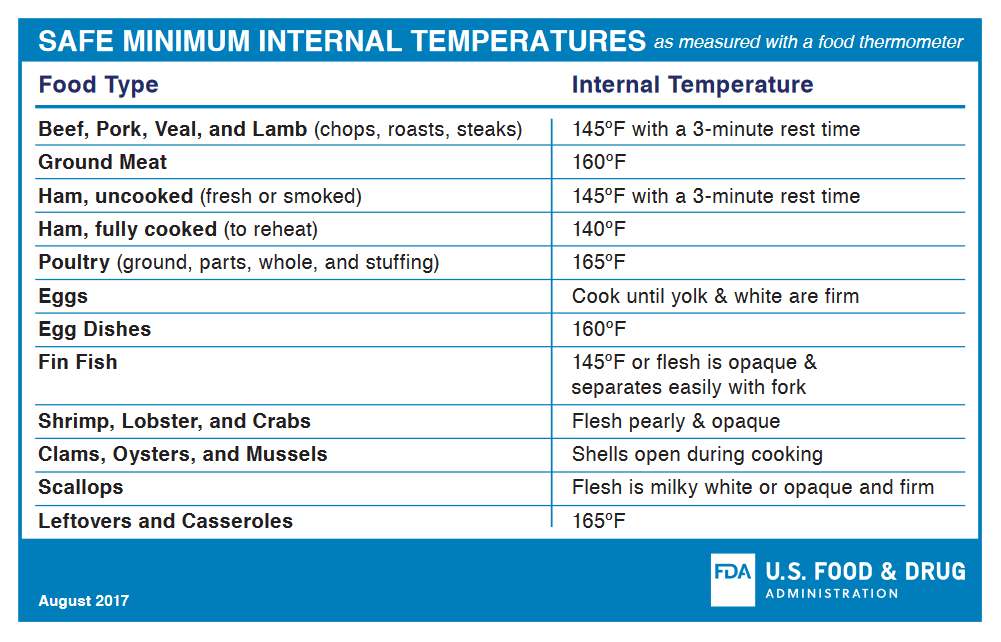

Microbes aren’t smart. They don’t sit around waiting for the 165F safe internal temperature for chicken (as deemed by the FDA below) and die. The 165F chosen by the FDA is based on a bit of science and statistics and by using the same tricks you can actually go lower.

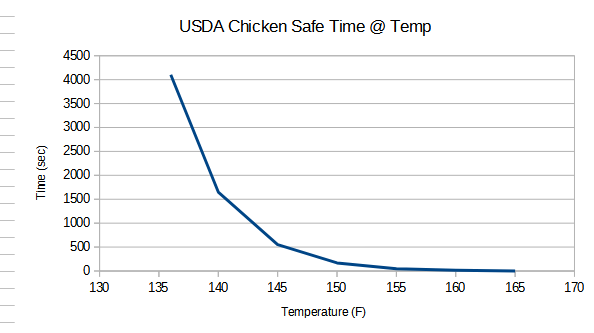

Microbe death follows a first order death equation dN = -k*N*dt where N is the size of the microbial population and k is the death rate. Where the factor k itself follows k = A*exp(-E/RT). Long story short, the decrease in a microbial population size is affected by time and temperature (different microbes behave differently).

This equation isn’t used too much in industry instead going with decimal reduction time z= (T2-T1)/[log(D1)-log(D2)] which defines the time required to reduce a microbial count by 90%.

What this all boils down to (great pun), is that the FDA safe internal temperatures values are based on the temperature at which we see a 7 log10 reduction in microbial content instantaneously. This is good for the government as their recommendation is very conservative and they can’t be blamed for anything other than dry chicken.

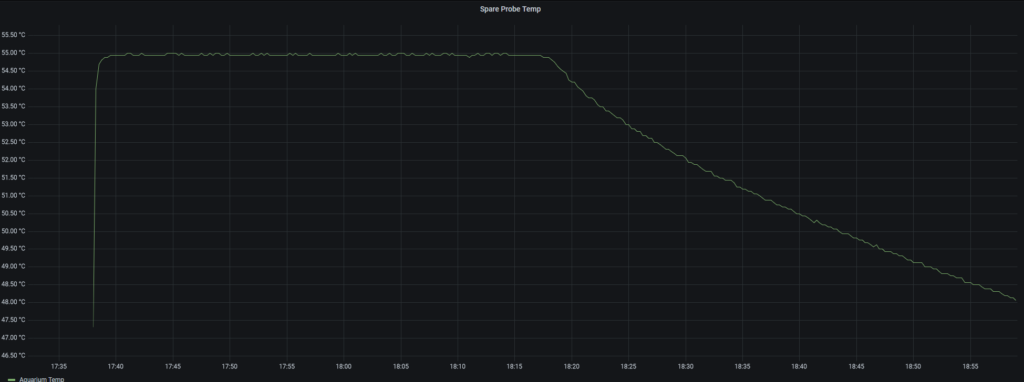

To cheat the system we can achieve the same 7 log10 reduction at a lower temperature but a longer time. There are curves for this but for example with chicken we can achieve this with 58c for 64 minutes meaning we can have both safe and juicy chicken (talk about having your cake and eating it too).

This is cool and all but the astute will note that a 7 log reduction is 99.99999% effective but not 0 and microbes just like cockroaches will multiply. If you leave one alive it will come back with more. For this the government uses a bit of statistics and for shell stable foods uses a 12 log reduction. Now a 12 log reduction also doesn’t guarantee 0 microbes but we get down to such small numbers that spoilage probability and economics take over. For a given set of starting microbes, a 12 log reduction and for R amount of containers you can estimate how many containers will have microbes out of a batch and if it an acceptable amount. So unfortunately the chances of buying processed food and having food poisoning are never 0 but are managed to safe levels.