Data Analytics

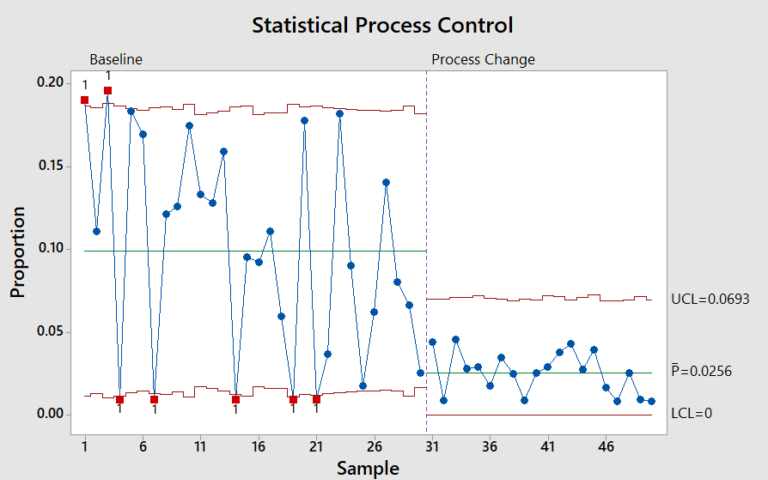

Experience with Big Data analytics tools with Python, SQL & Power BI. Lean Six Sigma Black Belt, experience in statistical…

I am a chemical engineer from the University of Waterloo with a specialization in Chemical Process Modelling, Optimization and Control. I push for data driven process optimization and KPI analysis to properly push for business success.

Experience with Big Data analytics tools with Python, SQL & Power BI. Lean Six Sigma Black Belt, experience in statistical…

Process engineering experience in automotive and food manufacturing. Continuous improvement leader of waste reductions, quality and cost projects. Experience in…

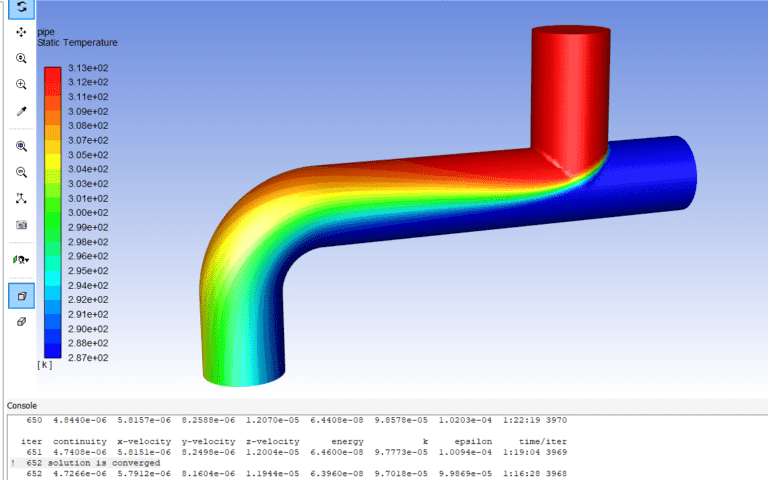

Process simulation experience in COMSOL & ANSYS for material & heat transfer applications. Simulation of heat transfer through heterogeneous food…

Education:

University Of Waterloo: Chemical Engineering, Honours & Distinction, Chemical Process Modelling, Optimization and Control Specialization

Process Engineer / Data Analyst

Magna International

Managed department KPIs, breaking down monthly variances and investigated opportunities. Led cross functional projects to drive KPI improvements and ensure business success. Made data driven decisions to ultimately reduce net costs. Led process optimizations projects, improving process yields, uptime, and material optimizations. Created tools for the team to better manage BOMs, new product launches and maintain process stability.

Spearheaded Power Bi adoption by creating new & simplified reports, automatic alerts for out of control data and automated weekly process summaries. Minitab statistical analysis for understanding out of control processes and facilitating root cause investigations. Created complex DOE for new material/equipment trials and ANOVA analysis for material optimizations trials.

Project Engineer

Mondelez International / Kraft

Developed and secured CAPEX funding for a new recycle process to reduce waste in the production

process. Designed a new automated data collection system to track production CTQ parameters and

provide SPC while ensuring information security and ease of use. Worked with multidisciplinary

teams to ensure everyone’s needs were met and frequently followed up to ensure project satisfaction

from all key stakeholders and end users.

Engineering Specialist

Toyota Motor Manufacturing

Conducted full production trials, validation and analysis for new materials to reduce cost of

manufacturing while maintaining quality KPI for customers. Preformed in depth data and statistical

analysis to find the root cause of a production defect outbreak and tracked process changes ensuring

that the outbreak was resolved in an efficient and documented manner. Created a design of

experiments on key process variables to understand factor effects and interactions on the process and

to find optimal setpoints for operation of new equipment.